LOGIN

If you have forgotten your login details please send an email to: info@meatmessaging.com

An Introduction to Meat Messaging

Meat Messaging is an industry program administered by AUS-MEAT with program management through an industry committee (RMSCC) comprising representatives from AMIC, AMPC, MLA, AUS-MEAT, DAFF, GS1 and industry members. Meat Messaging has been initially funded through a number of Industry funding arrangements. In 2017 the industry committee agreed, through industry consultation, that Meat Messaging was to be funded through a "Cost Recovery" model based on billing for each message uploaded to Meat Messaging. In 2022 the industry committee published this model which included a proposed time frame and fee structure, along with a process for adjusting the fee structure on a regular basis to maintain Meat Messaging. For more information on the Meat Messaging cost recovery model contact AUS-MEAT on ausmeat@ausmeat.com.au or 1800 621 903.

Meat Messaging Mobile App

The Meat Messaging progressive web app (PWA) is designed to work on mobile devices and supports barcode scanning either through a mobile device camera or ideally through a web browser enabled mobile device that has an inbuilt barcode scanner. The Meat Messaging progressive web app is accessible at https://app.meatmessaging.org/

How Does Meat Messaging Work?

The Meat Messaging registered Australian exporting establishments' IT management system sends a Meat Messaging Message to the Meat Messaging portal for EVERY shipment that leaves the establishment. The industry program holds the meat consignment information in a secure standards-based industry cloud portal. The Meat Messaging message information that is uploaded to the Meat Messaging portal is the same information that can be accessed on the physical carton/case/carcase. The Meat Messaging industry portal is accessed by supply chain participants and regulatory authorities to determine the authenticity, verification and traceability of meat products. Refer to the DAFF Meat Notices for more details Available here. The uploaded message information can be accessed by the client or import inspection facility in advance through the health certificate or carton/case/pallet barcode information.

The Meat Messaging program is based on the use GS1 bar coding standards and GS1 EANCOM electronic message standards. These GS1 standards do not replace existing regulatory requirements, they assist and supplement these requirements. For more details of the GS1 standards as they apply to the Meat Industry refer to the RMSCC website Available here. Once a company has registered to use Meat Messaging, they have to demonstrate competence in using the Meat Messaging web portal in the test environment. After this process is complete, they will receive approval from DAFF and FSIS and the Australian Meat Exporting Establishment will be listed on the FSIS Import Inspection Operations SharePoint site allowing for approval to rectify missing shipping marks on cartons through this directive.

Introduction to Meat Messaging Learning Resource

The "Introduction to Meat Messaging" Learning Resource is a comprehensive, interactive training program designed to empower learners with the knowledge needed to effectively implement the Meat Messaging system for use with Export Messages, eMTCs and Domestic Messages.

An Export Establishment's key personnel need to have completed the Introduction to Meat Messaging course before the Export Establishment can move from the implementation/ testing phase to commercial/ regulatory use of the Meat Messaging system. For more information on the Meat Messaging Learning Resource go to the AUS-MEAT Training Portal.

12 Commercial Benefits of Using Meat Messaging

1. Ability to Remark Damaged or Missing Shipping Marks to the U.S.

For the U.S. market, Meat Messaging is used for remarking for damaged or missing shipping marks which immediately allows the lot to move as a unit.

Outline for:

- Australian Export Establishments

- U.S. Import Inspection Establishments

2. Send Cartons to the U.S. without Shipping Marks

For the U.S. market, Meat Messaging can be used for compliance to the FSIS protocol for sending cartons without needing to apply shipping marks to individual cartons.

Outline for:

- Australian Export Establishments

- U.S. Import Inspection Establishments

3. Government Recognised Traceability Validation Tool can be used to respond to issues raised by Government Agencies

Meat Messaging is a government recognised traceability validation tool from the export registered Meat establishment all the way through to the end-user.

Outline for:

- Australian Export Establishments

- U.S. Import Inspection Establishments

4. Carries Product Providence Claims

Greatly increased end-user visibility of supply chain movements, improved traceability and product providence validation.

Outline for:

- Australian Export Establishments

- Cold Stores

- Non Packer Exporters

- Foreign Import Countries

5. End-Users can Access Shipment information before it Arrives

Meat Messaging provides a simple solution for supply chain visibility as it allows the end-users to be able to access all the production data for a shipment before the shipment arrives.

Outline for:

- Australian Export Establishments

- Cold Stores

- Non Packer Exporters

- Foreign Import Countries

6. Acts as a Product Translation Tool for Foreign Speaking Countries

Meat Messaging is used as a product translation tool for countries that don’t speak English.

Outline for:

- Australian Export Establishments

- Cold Stores

- Non Packer Exporters

- Foreign Import Countries

- Government

7. Time Taken on MTC's Drastically Reduced

Establishments that have started using eMTCs through integration with the on-plant systems have seen the time taken related to MTC management drop from hours per day to no time being spent on MTCs at all.

Outline for:

- Australian Export Establishments

8. Time Taken on Manual Paper Recording Drastically Reduced

Where establishments have fully implemented Meat Messaging through integration with the on-plant systems, the time taken at loadout related to manual paper recording activities for export loads, eMTCs and domestication has all but vanished.

Outline for:

- Australian Export Establishments

- Cold Stores

- Non Packer Exporters

9. Provides Real-Time Assurances on Product Safety and Integrity

The ability to move to annual DAFF audits through the use of Meat Messaging by having the capacity to provide real-time assurances on product safety and integrity.

Outline for:

- Australian Export Establishments

- Cold Stores

- Non Packer Exporters

- Foreign Import Countries

- Government

10. Ensure Market Eligibility on a Carton Level

Ensuring and demonstrating market eligibility on a carton level through the export supply chain from the processor through to the importing country inspection.

Outline for:

- Australian Export Establishments

- Cold Stores

- Non Packer Exporters

11. Provides all the information that is on a paper or electronic certificate

Importers and end-users still rely on paper certificates or the data from ecert. The system provides all the information that is on a paper or electronic certificate.

Outline for:

- Australian Export Establishments

12. Allows for Future Possibility to Regulatory Changes for Lab Sampling

The system allows for further possible regulatory changes (next steps) to sampling and inspection.

Outline for:

- Australian Export Establishments

- Cold Stores

- Non Packer Exporters

- Government

How Meat Messaging Facilitates Official Import Facility Remarking to the U.S.A

The industry portal and related activities are documented in Australian Meat Notice 2018-01 and meets the requirements of FSIS Directive 9900.5, Section VII, E.Procedures for Correcting Shipping Marks when Using Barcodes for the use of the industry portal for carton/carcase verification.

Correcting Shipping Marks

- Import Establishment can correct shipping marks without having a representative of the foreign government to supervise

- Only when FSIS can verify the unique identifier within a barcode on the shipping unit using supporting documentation from the foreign country.

Supporting Documents Available

- Supporting Documentation is available for Australian products through Meat Messaging

- Meat Messaging System can be accessed by import establishment to view barcodes linked to the certificate

- Same Day at no Cost

![]()

Accessible for Countries that are Eligible

- Only allowed for countries that are eligible & only applies to establishments approved for such activity

- Australia is eligible and FSIS inspection personnel maintain a list of approved Australian establishments in the FSIS internal SharePoint site they access to verify eligibility.

Replace Paper MTC's

- The industry portal and related activities are documented in Australian Meat Notice 2018-01 and meets the requirements of FSIS Directive 9900.5 for the use of the industry portal for carton/carcase verification.

- Under section E. Procedures for Correcting Shipping Marks when Using Barcodes - FSIS permits official import inspection establishment personnel to apply the shipping mark to shipping units without having an official representative of the foreign inspection system on-site to approve and observe this activity, when FSIS IPP can verify the unique identifier within a barcode on the shipping unit using supporting documentation provided by the foreign country.

Australian Meat Exporters Can Now Send Cartons to the U.S. Without Shipping Marks on Individual Cartons.

FSIS Directive 9910.1 states that Australian Exporters can use placards on slip-sheet shrink-wrapped pallets that are associated with all the individual cartons/cases. Shipments complying with this directive are only to move intact to official establishments within the U.S. for further processing. This process provides the required level of carton traceability. The use of the pallets and placards is instead of applying individual shipping identification marks to each meat carton/case. The placard acts as the identification linked to the health certificate.

Current Process

Australia Shipping Mark

Instead of Australia applying their shipping mark on products shipped to U.S. the barcodes on the pallet placard and individual cases will be used to verify approved Australian product in lieu of the shipping mark.

USDA Official Import Mark

Instead of applying the USDA official import mark of inspection to the individual cases, the mark is applied only to the barcode placard on each pallet in the shipment.

Pallet Wrapping

Inspection personnel will perform label verification without removing the plastic wrapped around the pallet, as long as the label attributes are visually identifiable.

Slip Sheets

Placing slip sheets on each crate when loading and unloading is pivotal. Adding slip sheets to the top of crates, whether it is placing the block into the container or removing it from the container, slip sheets need to be on the top and bottom of the block with machine wrap.

FSIS Directive 9910.1 Process

The Meat Messaging Pallet Pilot

Download the Pallet Pilot Report

Reducing Labour Costs through Slip Sheets

Meat Messaging pallet pilot uses a slip sheet palletising with Serial Shipping Container Code (SSCC) pallet labels as a replacement for individual carton/case shipping marks.

The time saving for the unloading/inspection has been shown to be reduced to

2 people 45 minutes instead of 5 people for 45 minutes to unload a container.

A 2019 pallet pilot to Philadelphia, U.S.A demonstrated this

Damaged pallets without slip sheets

Upon the final shipment of the latest pallet pilot, three boxes were rejected from the shipment because the top of the boxes were ripped from the "teeth" of the forklift by human error.

The images shown in below are from the pallet pilot and show the damage that can be done without having a slip sheet on the top of the crate. Pallets must have slip sheets placed on the top and bottom of the pallet.

Care needs to also be placed when loading them, ensuring the sides of the stacked pallets are even with each other. The pallets plastic wrap will help maintain this even side and provide a protective layer around the cases.

Cartons damaged by forklift picking up pallet stacked on top of them.

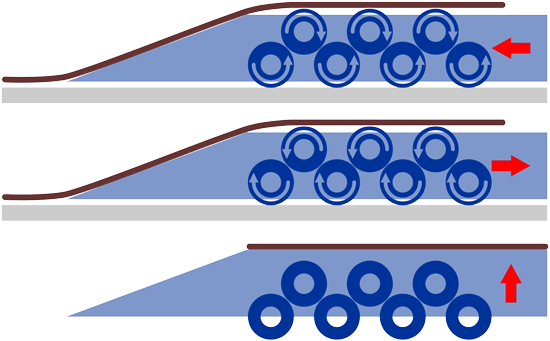

Using Roller Forks for Loading and Unloading: How do they work?

The Roller Forks can be used for palletless handling. Roller Forks are in fact 'standard' lift truck forks with two layers of rollers. When the under most row of rollers touches the floor, it causes the uppermost rollers to rotate in the opposite direction whereby the forks slide under the slip sheet without disturbing the products.

When the forks are lifted up, the rollers 'fall' downwards and place the products securely on the upper side of the forks, enabling the products to be unloaded in the opposite loading order and works with shipping container floors.

A roller fork consists of a special lift truck fork that serves as a supporting frame with a special hinge in the heel allowing it to always lay flat on the floor. Inside the fork are two layers of rollers, one on top of the other, that drive each other when the forks are moved over the floor.

The basic principle is that the upper rollers rotate at exactly the same speed but in the opposite direction of the lower rollers, which are in contact with the ground. When the Roller Forks are lifted up from the ground the rollers automatically lower and the load is held on the forks.